Cutting out

Strip cutting is a common operation in the production of metal parts. This operation consists in separating all or part of the zones of a strip to obtain the desired shape. Cutting is also useful for routing parts, whether to remove burrs from a previous operation or to remove a part from a foundry cluster.

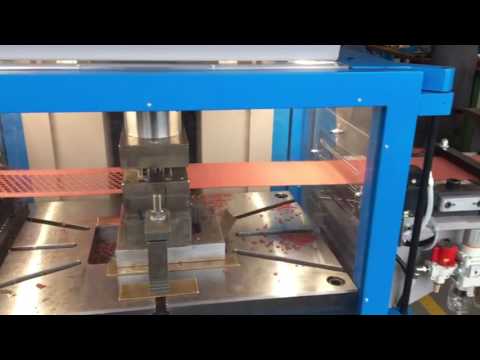

One of the most common solutions used in industry is the use of mechanical presses or pneumatic presses to cut all kinds of parts.

Cutting with a pneumatic or mechanical press

Whether pneumatic or mechanical, a press can cut all types of material (steel, aluminum, stainless steel...), whatever the shape of the metal parts to be machined. The power of the press must be adapted to the thickness (up to several millimeters) and characteristics of each material in order to obtain perfect cutting results. The depth of the gooseneck determines the length and width of the parts to be cut.

Press cutting: everything you need to know about this versatile tool

Whether pneumatic or mechanical, a press equipped with the right tools can cut all types of materials (steel, aluminum, stainless steel, etc.), whatever the shape of the metal parts to be machined. The power of the press must be adapted to the thickness (up to several millimeters) and characteristics of each material in order to obtain perfect cutting results. The depth of the gooseneck determines the length and width of the parts to be cut.

What is a die-cutting press and how does it work?

A die-cutting press is an industrial tool that uses mechanical force to cut various materials such as steel, aluminum or stainless steel. Different technologies, depending on the type of press chosen, enable the necessary pressure to be applied in a perfectly linear axis to produce precise cuts.

The different types of die-cutting presses and their uses

There are two main types of press particularly suited to this application: mechanical and pneumatic. Pneumatic presses are ideal for small to medium-scale production runs, while mechanical presses are more suited to large-scale production runs, enabling a large number of parts to be processed rapidly. The power of these EMG presses enables effortless, burr-free, high-precision cutting. An effort management system monitors production quality.

The presses can be integrated into production lines comprising unwinders, straighteners and feeders, and can operate at speeds of up to 240 strokes per minute on the 6T press.

Mechanical presses thus enable rapid processing of a very large number of parts, with a simple feeder process right through to the removal of each part in total safety for the operator.

The advantages of using a press for cutting operations in your workshop

As a manufacturer of presses for assembly, stamping, bending and riveting operations, we have long experience and expertise recognized by our customers.

Our wide range of machines can meet the vast majority of your needs. Nevertheless, if your activity requires adaptations for specific cutting tooling, our know-how enables us to provide you with a fully adapted solution. We design special machines and customized equipment to your specifications.

Cutting: faster, more efficient presses boost productivity

The use of a die-cutting press can considerably boost your workshop's productivity. Thanks to their speed of execution, these presses reduce the time spent on each cutting operation.

Lower production costs thanks to automation and the use of less expensive materials

Our cutting presses can be integrated into systems that can be automated, for example to create a raw material feed system, which not only reduces production costs but also maintains maximum cutting quality.

How to choose the right die-cutting press for your specific needs?

How to choose your die-cutting press? Which press is best suited to cutting the parts you're machining? Simple theoretical calculations can be used to estimate power requirements for all cutting operations.

Important considerations when choosing a die-cutting press

When choosing a press, several criteria must be taken into account to guarantee efficient cutting adapted to your production:

-load capacity

- machine size,

- technical features such as stroke and overall dimensions.

Tips for long-term, efficient use of a press in your cutting processes

Whatever your press, regular maintenance is essential. Maintaining it and carrying out maintenance operations at the right times will extend the life of your machine.

Best practices for operator safety when using a cutting press

Operator safety is one of our main concerns. Our machines are designed to enhance operators' working comfort. Our teams can provide support:

- to help you set up the workstation and implement all safety measures

- to ensure that users are trained in good press operating practices.

Regular maintenance and upkeep to extend the life of your cutting press

As with any machine, regular maintenance is one of the keys to prolonging the life of your press. By carrying out regular checks and repairs, you can guarantee optimal operation and consistent precision in your die-cuts.

Our technical department offers preventive maintenance contracts, while carrying out the mandatory periodic checks.

With EMG, make the right choice for your cutting operations and optimize your production.

Whether for small or large production runs, mechanical or pneumatic presses can meet your requirements.

EMG presses offer outstanding quality and precision for both craft and industrial die-cutting. They also guarantee optimum speed of execution, particularly when large-scale production is required.

Don't hesitate to contact us for personalized advice and to choose the right tool for your specific needs, whether for die-cutting or other industrial applications such as assembly, bending or marking.